Plasma Food Sterilizers Market to Reach USD 1,048 Mn by 2035 as Cold Plasma Technology Redefines Food Safety Standards

Prominent players in the market are Plasmapp, Adtec Plasma Technology / Adtec Healthcare, Plasmatreat GmbH, Henniker Plasma, Europlasma NV

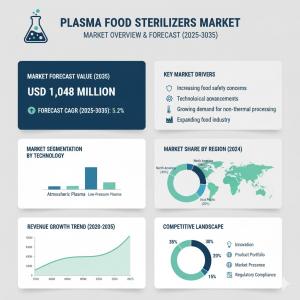

ROCKVILLE, MD, UNITED STATES, October 23, 2025 /EINPresswire.com/ -- The global plasma food sterilizers market is gaining significant momentum as food manufacturers increasingly adopt advanced sterilization technologies to ensure product safety, extend shelf life, and maintain nutritional integrity. According to a recent report by Fact.MR, the market is projected to grow from USD 631 million in 2025 to USD 1,048 million by 2035, registering a robust CAGR of 5.2% during the forecast period.The surge in foodborne illness prevention initiatives, along with the global shift toward chemical-free and energy-efficient sterilization methods, is driving widespread adoption of plasma-based sterilizers. These systems, which utilize cold plasma technology, offer a sustainable and effective alternative to conventional heat or chemical sterilization—making them ideal for sensitive food products such as dairy, fruits, and ready-to-eat meals.

Strategic Market Drivers:

Growing Focus on Food Safety and Shelf-life Extension

Stringent food safety regulations and rising global food trade have compelled processors to adopt sterilization technologies that ensure microbial decontamination without compromising taste or texture. Plasma sterilization achieves pathogen inactivation through reactive oxygen and nitrogen species, offering an eco-friendly and residue-free sterilization approach.

Technological Advancements in Plasma Sterilization Systems

Continuous innovations in plasma generation, electrode design, and treatment chambers are enhancing efficiency and scalability. Manufacturers are developing compact, automated systems compatible with different packaging materials and production lines. These advancements are boosting adoption across medium and large-scale food processing facilities.

Sustainability and Non-Thermal Processing Advantages

With the global focus shifting toward clean-label and minimally processed foods, plasma sterilizers are emerging as a green alternative. The technology consumes less energy, produces no harmful residues, and aligns with circular economy initiatives—making it a preferred choice among sustainability-driven manufacturers.

Regional Growth Highlights

East Asia: Epicenter of Technological Adoption

East Asia, particularly China, Japan, and South Korea, dominates the plasma food sterilizers market, supported by a robust manufacturing ecosystem and rapid technological innovation. The region’s strong packaging and electronics industries further support advancements in plasma equipment design and integration.

North America: Driven by Food Safety Regulations

The United States and Canada are witnessing growing adoption due to strict FDA and USDA regulations emphasizing food safety and shelf stability. Leading food producers and technology firms are investing in pilot-scale plasma systems, with significant applications in meat, dairy, and produce sterilization.

Europe: Sustainability and Innovation Hub

Europe continues to lead in sustainability-driven innovation, with the EU’s “Farm to Fork” strategy promoting non-thermal, eco-friendly sterilization methods. Countries such as Germany, France, and the Netherlands are focusing on commercializing plasma sterilizers for both industrial and small-scale food processors.

Emerging Markets: Rising Urbanization and Processed Food Demand

Latin America and the Middle East present growing opportunities as consumers shift toward processed and packaged foods. Increasing awareness of food hygiene and international export standards is fostering demand for advanced sterilization technologies in these regions.

Market Segmentation Insights

By Type

Cold Plasma Sterilizers: Leading segment due to their compatibility with heat-sensitive foods and packaging materials.

Thermal Plasma Sterilizers: Used in high-throughput industrial settings where rapid sterilization is required.

By Application

Dairy and Beverages: Ensuring microbial safety while preserving flavor and nutrients.

Meat and Seafood: Preventing spoilage and extending shelf life.

Fruits and Vegetables: Non-destructive surface sterilization for fresh produce.

Ready-to-Eat and Packaged Foods: Enhancing safety in pre-packed meal processing lines.

By End User

Food Processing Industries

Packaging Companies

Research Laboratories and Universities

Challenges and Market Considerations:

High Initial Investment: Plasma sterilization equipment involves high R&D and installation costs, limiting adoption among small-scale producers.

Limited Standardization: Lack of harmonized global standards for plasma sterilization poses regulatory hurdles.

Process Optimization: Achieving uniform plasma exposure for diverse food geometries remains a technical challenge.

Awareness Gap: Market penetration is hindered in developing regions due to limited awareness about non-thermal sterilization benefits.

Competitive Landscape:

The plasma food sterilizers market features a mix of established manufacturers and emerging technology providers.

Key players include:

Plasmapp, Adtec Plasma Technology / Adtec Healthcare, Plasmatreat GmbH, Henniker Plasma, Europlasma NV, Tuttnauer, Steris Corporation, Getinge AB, PlasmaLeap Technologies, and AcXys Technologies.

These companies are actively developing modular, scalable plasma systems that meet global safety standards while enhancing operational efficiency. Strategic partnerships with food processors, packaging manufacturers, and research institutions are pivotal to accelerating commercialization.

Recent Developments

July 2025: Adtec Healthcare (Adtec Plasma Technology group) announced a major funding round aimed at accelerating the global rollout of its cold-plasma sterilization models. The initiative supports expansion into food and packaging sectors, underscoring growing cross-industry adoption of cold plasma platforms.

June 2024: Plasmapp launched STERLINK™ FPS-15s Plus, a compact plasma sterilization system (<20L capacity) designed for small processors and clinics. The model achieved regulatory certification, offering an efficient low-temperature sterilization solution for limited-scale food applications.

Future Outlook: Toward a Safer, Greener Food Ecosystem

The next decade will be crucial for the plasma food sterilizers market as the food industry transitions toward cleaner, energy-efficient, and sustainable processing methods. Plasma-based sterilization is expected to play a central role in reducing foodborne pathogens, lowering energy use, and minimizing chemical dependencies.

Manufacturers that integrate plasma technology with automation, IoT monitoring, and sustainable design will gain a competitive edge. With strong momentum in innovation and regulatory support for non-thermal technologies, the plasma food sterilizers market is set to transform global food safety standards—ushering in a safer, greener, and smarter era of food processing.

Request for Discount: https://www.factmr.com/connectus/sample?flag=S&rep_id=11241

Buy Now at USD 2900: https://www.factmr.com/checkout/11241

Check out More Related Studies Published by Fact.MR Research:

Sterilization Services Market Outlook (2024 to 2034) - https://www.factmr.com/report/sterilization-services-market

Cold Plasma Market Outlook (2024 to 2034) - https://www.factmr.com/report/cold-plasma-market

Medical Device Cleaning Market Outlook (2025 to 2035) - https://www.factmr.com/report/medical-device-cleaning-market

Sterilization Monitoring Technologies Market Outlook 2025 to 2035 - https://www.factmr.com/report/sterilization-monitoring-technologies-market

Editor’s Note:

The Plasma Food Sterilizers Market represents a pivotal advancement in the global food processing and safety ecosystem. As the industry shifts toward sustainable, non-thermal sterilization technologies, plasma-based systems are emerging as a transformative solution—offering superior microbial control, minimal nutrient loss, and alignment with clean-label production goals. The technology’s scalability, energy efficiency, and compatibility with diverse food categories position it as a cornerstone for the next generation of food safety innovation.

S. N. Jha

Fact.MR

+1 628-251-1583

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.